+86 0563-4309002

+86 17705630058

vickyw@gaoxincn.com

Self-developed, Self-used,Field-proven. With 20+ years of casting expertise,Qasim delivers not just machines —but performance andpeace of mind.

Quality Control

At Q-GrindingMedia, quality is the cornerstone of our reputation. We implement a rigorous

quality control system throughout every stage of our cast grinding media ball production

— from raw material inspection to final product testing. Our commitment ensures that

each batch meets the highest international standards for performance, durability, and safety.

Our Quality Control Process

1.Raw Material Inspection

All incoming raw materials are strictly inspected for chemical composition and cleanliness.

All incoming raw materials are strictly inspected for chemical composition and cleanliness.

Certified suppliers and material traceability are maintained for consistency and accountability.

Certified suppliers and material traceability are maintained for consistency and accountability.

2.Melting & Chemical Analysis

Spectrometer analysis is conducted during melting to ensure the required alloy content is achieved.

Spectrometer analysis is conducted during melting to ensure the required alloy content is achieved.

Each heat is tested before pouring to confirm it meets chemical specification requirements.

Each heat is tested before pouring to confirm it meets chemical specification requirements.

3.Mold & Pouring Control

Precision molding technology and controlled pouring temperatures reduce defects such as porosity or shrinkage.

Precision molding technology and controlled pouring temperatures reduce defects such as porosity or shrinkage.

Each batch is assigned a unique traceability code.

Each batch is assigned a unique traceability code.

4.Heat Treatment Monitoring

Advanced heat treatment furnaces are equipped with real-time temperature control and data logging.

Advanced heat treatment furnaces are equipped with real-time temperature control and data logging.

Quenching and tempering parameters are tailored to optimize hardness and toughness.

Quenching and tempering parameters are tailored to optimize hardness and toughness.

5.Dimensional & Surface Inspection

Random sampling of each batch is checked for size tolerance, roundness, and surface integrity.

Random sampling of each batch is checked for size tolerance, roundness, and surface integrity.

Manual and automated inspection procedures ensure consistency.

Manual and automated inspection procedures ensure consistency.

6.Mechanical Properties Testing

Hardness Test (HRC): To ensure uniform hardness throughout the ball.

Hardness Test (HRC): To ensure uniform hardness throughout the ball.

Impact Toughness Test: Conducted to evaluate resistance to breakage under high-stress conditions.

Impact Toughness Test: Conducted to evaluate resistance to breakage under high-stress conditions.

Metallographic Examination: Carried out to assess the internal microstructure for uniformity and phase distribution.

Metallographic Examination: Carried out to assess the internal microstructure for uniformity and phase distribution.

7.Final Product Testing

Sampling of finished products undergoes destructive and non-destructive testing.

Sampling of finished products undergoes destructive and non-destructive testing.

Each lot is accompanied by a quality certificate before shipment.

Each lot is accompanied by a quality certificate before shipment.

Key Testing Equipment We Use

Spectrometer – For fast and accurate chemical composition analysis.

Spectrometer – For fast and accurate chemical composition analysis.

Rockwell & Brinell Hardness Testers – To verify surface and core hardness.

Rockwell & Brinell Hardness Testers – To verify surface and core hardness.

Drop Ball Test Machine – Simulates real grinding conditions for toughness validation.

Drop Ball Test Machine – Simulates real grinding conditions for toughness validation.

Impact Testing Machine – Measures energy absorption capacity under sudden loads.

Impact Testing Machine – Measures energy absorption capacity under sudden loads.

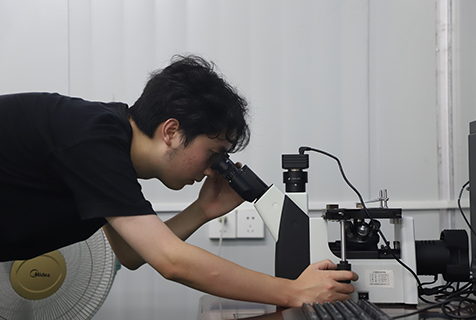

Microscope & Metallographic Equipment – Analyzes the grain structure and detects defects.

Microscope & Metallographic Equipment – Analyzes the grain structure and detects defects.

Heat Treatment Recorders – Tracks temperature profiles in real time for full heat treatment traceability.

Heat Treatment Recorders – Tracks temperature profiles in real time for full heat treatment traceability.

Our Promise

Every grinding media ball we produce is backed by strict quality control, technical know-how,

and customer transparency. Our quality assurance team works closely with our production staff

to continually monitor, improve, and refine our processes. With Q-GrindingMedia, you can be

confident you're working with a partner who prioritizes performance and reliability above all.

Comment

(0)